What is the Purpose of Inverters?

Whereas dc machines are controlled by varying the voltage and current, ac machines are often controlled by varying the voltage and frequency. One way of accomplishing this is by using inverters. The process of converting ac from dc is referred to as inversion. Some of the reasons why ac machines are preferred over dc machines include:

- AC machines have no commutations; as a result, they require less maintenance.

- AC machines cost less; also they weigh less than dc machines.

- AC machines are more rugged and work better in harsh environs.

Types of AC Drives

Generally, ac drives may be classified into the following classes:

- Static frequency changers.

- Variable voltage controllers.

- Rectifier-inverter systems with natural commutation.

- Rectifier-inverter systems with self-commutation.

Static frequency changers convert the incoming line frequency directly into the desired load frequency. Cycloconverters fall into this category, and they are used to drive both synchronous and squirrel-cage induction motors.

Variable voltage controllers enable speed and torque control by varying the ac voltage. They are used in squirrel-cage and wound-rotor induction motors. This technique of speed control is the least expensive of all, and offers a satisfactory solution for small and medium machines used on fans, centrifugal pumps and electric hoists.

Rectifier-inverter systems rectify the incoming line frequency to dc, and the dc is reconverted to ac by the inverter. The inverter may be self-commutated, generating its own frequency, or it may be naturally-commutated by the very motor it drives. Such rectifier-inverter systems with a dc link are used to control-squirrel-cage and wound-rotor induction motors, in some cases synchronous motors.

Single-phase Inverter Features & Operation

To illustrate the basis of operation of an inverter, let’s consider an illustration of a single-phase inverter below:

This inverter utilizes IGBTs as the switching devices, with diodes to provide the freewheel paths required when the load is inductive.

Recommended: The Ultimate Guide to Electrical Maintenance

The input or dc side of the inverter is usually called the ‘dc link’, reflecting the fact that in most of the cases the dc is obtained by rectifying the incoming constant-frequency utility supply. The output of ac side is taken from terminals A and B.

The operation of this inverter is as follows:

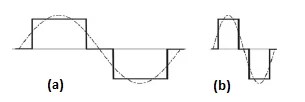

When transistors 1 and 4 are switched ON, the load voltage is positive, and equal to the dc link voltage, while when 2 and 3 are ON it is negative. If no devices are switched ON, the output voltage is zero. Typical voltage waveforms at low and high switching frequencies are illustrated in figure 1.1 (a) and (b) respectively:

Each pair of devices is ON for one-third a cycle, all the devices are OFF two periods of one-sixth of a cycle. Whilst the output waveform is not a sine wave, it is alternating and symmetrical. Within each cycle the pattern of switching is regular and easily programmed using appropriate logic circuitry or generated in software. Frequency variation is achieved by altering the clock frequency controlling the 4-step switching pattern.

Inverters with the configuration as one shown in Figure 1.0 above and Figure 1.3 below are subject to a potentially damaging conditions which can arise if both transistors in one ‘leg’ of the dc inverter unintentionally turn ON simultaneously. If this happens, it will form short-circuit across the dc link. This fault condition is called a ‘shoot-through’ because a high current is established very rapidly, destroying the devices. A good inverter thus incorporates provision for protection against the possibility of shoot-through normally by imposing a minimum time-delay or dead-time between one device in the leg going OFF and the other coming ON.

Don’t miss out on key updates, join our newsletter List

Output Voltage Control

The amplitude of the output voltage can be controlled into ways:

First, the dc link is provided from the utility supply via a controlled rectifier or from a battery via a chopper; the dc link voltage can be varied. The amplitude of the output can therefore be set to any value within the range of the link voltage. For ac motor drives, we can arrange for the link voltage to track the output of the inverter, so that at high output frequency we obtain a high output voltage and vice versa. This method of voltage control results in a simple inverter, but requires a controlled and thus relatively expensive rectifier for the dc link.

The second method, dominates in all sizes, achieves voltage control by pulse-width modulation (PWM) within the inverter itself. A less costly uncontrolled rectifier can then be employed to provide a constant- voltage dc link.

The principle of voltage control by PMW is as follows:

At low output frequencies a low output voltage is usually needed, so one of each pair of devices is used to chop the voltage, the mark/space ratio being varied to achieve the desired voltage at the output. The low fundamental voltage component at low frequency is shown as a broken line in figure 1.2(a) below:

At higher frequency a higher voltage is required; therefore, the chopping device is allowed to conduct for a longer fraction of each cycle, giving the higher fundamental output in Figure 1.2(b). As the frequency is raised still higher, the separate ‘ON’ periods eventually merge, giving the waveform illustrated in figure 1.2(c) above. Any additionally increase in frequency takes place without further increase in the output voltage as shown in figure 1.2(d). This waveform in figure 1.2 (d) is usually termed to as ‘quasi-square’.

The switching nature of these converter circuit results in waveforms which contain not only the required fundamental component but also unwanted harmonic voltages. It is therefore important to limit the magnitude of the low-order harmonics as these are most likely to provoke an unwanted torque response from the motor, but the high-order harmonics can lead to acoustic noise if they happen to excite a mechanical resonance. The number, width and spacing of the pulses are thus optimized to keep the harmonic content as low as possible.

Three-phase Inverter Features

Most industrial applications employ 3-phase motors hence three-phase inverters find an extensive application in industrial motor control. A 3-phase output can be obtained by adding only two more switches to the four needed for a single-phase inverter, giving the typical power-circuit configuration illustrated below:

A freewheel diode is required in parallel with each transistor to protect against over voltages caused by an inductive (motor) load.

This circuit forms the basis of most converters for motor drives. Basically, the output voltage and frequency are controlled in much the same way as for the single-phase inverter however the output consists of three identical waveforms displaced by 120° from each other.

Related articles:

- Basic Features of Power Semiconductor Controlled Drives

- Industrial Motor Control Using Contactors

- Key Facts about Thyristor DC Motor Drives Operation

- Three-Phase Diode Bridge Rectifier: Function & Operation

Leave a Reply

You must be logged in to post a comment.